Automotive Core Tools

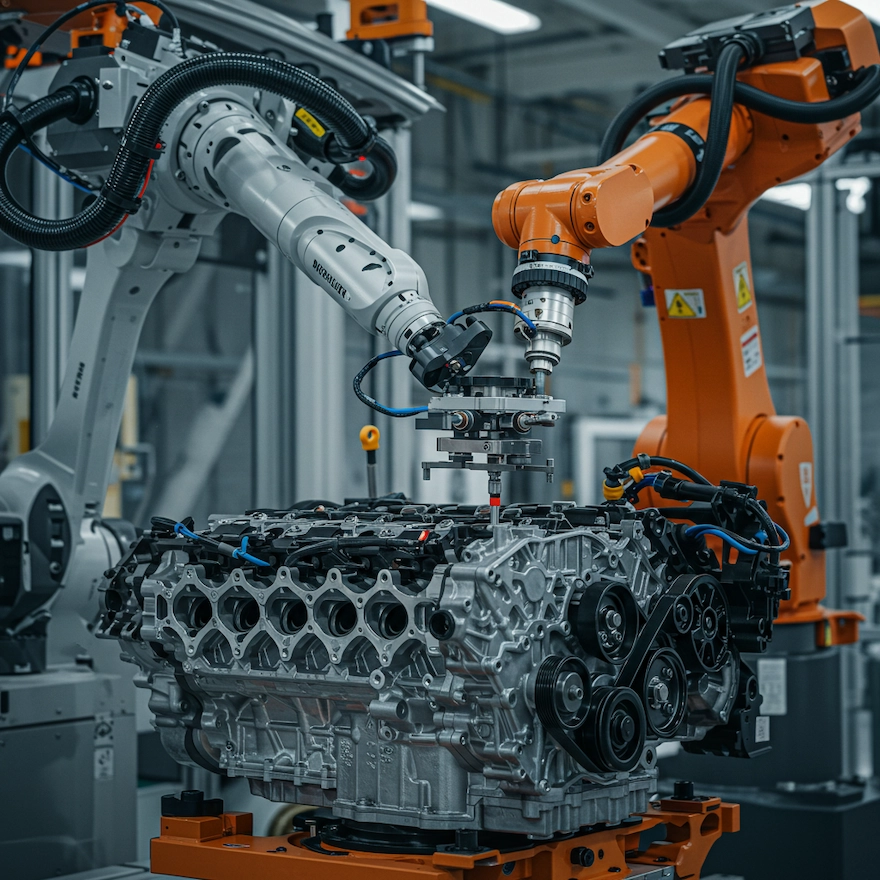

Master the automotive core tools importance for IATF 16949 compliance. This premier Malaysia program builds your quality management system foundation. Learn APQP methodology, FMEA risk assessment, MSA, PPAP, and SPC statistical process control. Gain quality problem-solving skills and defect prevention strategies using continuous improvement tools. Essential for new product introduction, process development quality, and meeting automotive supplier requirements.

Focus of Master Automotive Core Tools Training for Expert Supplier Quality Management in Malaysia

Master core tools for supplier quality and compliance.

Our Mission & Vision

Provide effective training and solutions that grow competitiveness of our clients.

Highlights of Master Automotive Core Tools Training for Expert Supplier Quality Management in Malaysia

Master automotive quality tools for optimized processes and practical expertise.

This program delivers immediate practical relevance through hands-on APQP workshops and interactive FMEA exercises. It’s led by instructors with deep automotive quality professional expertise. Youll gain skills for quality cost reduction and defect prevention optimization using real APQP case study examples. This proven blend drives real manufacturing efficiency improvement, making it superior to purely theoretical offerings.

Optimize manufacturing and quality with expert-led Automotive Core Tools training. Gain practical experience through hands-on workshops and real-world case studies. Book your seat now!

Frequently Asked Questions: 3C

FAQ 1. What COMPETENCY and skills will I gain from this training?

FAQ 2. Can the training be tailored or CUSTOMISED to our organizations specific needs?

FAQ 3. Will I receive a recognized qualification or CERTIFICATE?

Competency

Customization

Certificate

Master automotive quality with essential core tools training.

This program develops essential competency in automotive core tools like APQP and FMEA to ensure supplier quality, meet OEM requirements, reduce costs, and validate production processes.